POPULAR PRODUCTS

Vibratory Friction Welding Machine

Some Product Features:

Intelligent Control

High-Precision Welding

Quick Mold Change

Energy-Saving and Silent

Durable

Stable Performance

PRODUCTS

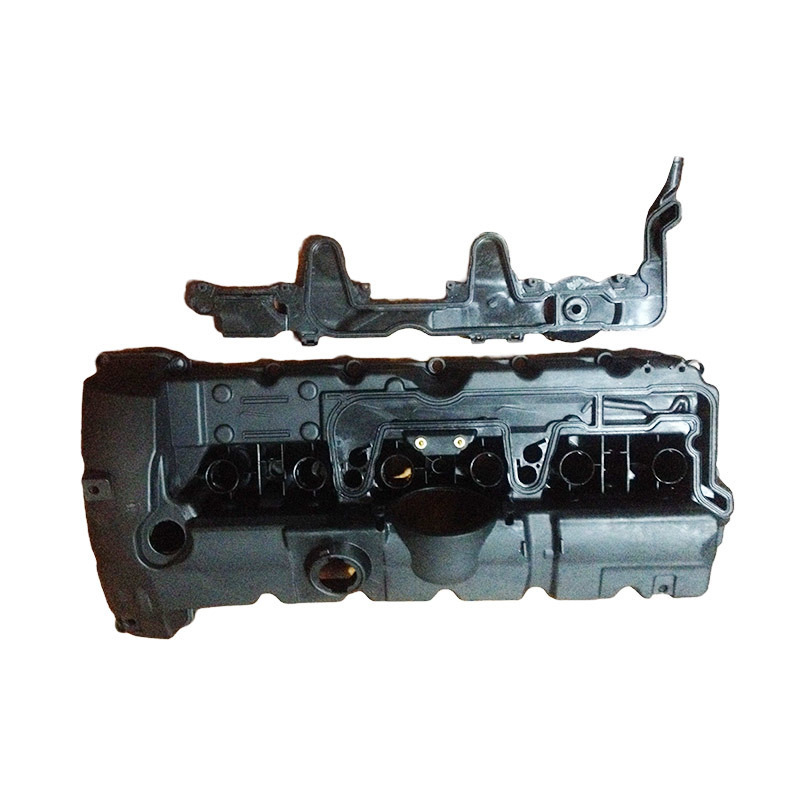

APPLICATION

The vibratory friction welding machine is suitable for almost all plastic welding with hard thermoplastic strength, including amorphous resins such as ABS/PC, PVC, PMMA and PES; Semi-crystalline resins such as HDPE, PA, PP, TPO, etc

ABOUT ALE

Zhejiang Ale Ultrasonic Technology Co., Ltd. was established in 2015, specializing in the field of plastic welding, integrating R&D, design, manufacturing, sales and service. Since its establishment, the company has implemented the concept of "industry craftsman spirit", and has a strong technical team with more than 10 years of experience in the same industry for many years...

Application Cases

Honors and qualifications obtained

The company was founded

Exported to many countries

ALE ADVANTAGES

Integrated professional service guarantee service quality

Company Service

Let you feel at ease, rest assured, intimate company service

Market Reputation

Widely trusted by the market

Visual Operational Control

Continue to strengthen market quality and create professional vibration welding technology, combined with market demand, and constantly develop new products with core competitiveness

NEWS CENTER

23

/

07

Exploring the Benefits of Vibration Welding Tooling in Automotive Applications

Exploring the Benefits of Vibration Welding Tooling in Automotive Applications As the automotive industry continuously seeks innovative solutions to enhance production processes, vibration welding tooling has emerged as a pivotal technology. This article delves deeply into the multifaceted benefits of vibration welding, illuminating its vital role in automotive manufacturing. Table of Contents

16

/

07

Friction Vibration Welding Machines: Innovative Solutions for Complex Joinery Challenges

Friction Vibration Welding Machines: Innovative Solutions for Complex Joinery Challenges Table of Contents 1. Introduction to Friction Vibration Welding 2. What is Friction Vibration Welding? 3. Advantages of Friction Vibration Welding Machines 4. Applications of Friction Vibration Welding in Various Industries 5. Technical Aspects of Friction Vibration Welding 6. Choosing

09

/

07

Understanding High Frequency Vibration Friction Welding Machines: Enhancing Industrial Efficiency

High frequency vibration friction welding machines represent a cutting-edge technology in the field of welding, particularly for industries requiring precise and efficient joining of materials. This technique is distinguished by its ability to produce strong welds while minimizing the input energy, making it an attractive option for manufacturers looking to improve their operational efficiency. Th

ALE Ultrasonic Equipment

Gather talents from all over the world and recruit good people.

Recruiting talents and talents

Seek truth and be pragmatic, build brilliant

Contact Us

Social respect, customer satisfaction